Connectivity and reliable connectors are at the heart of every military system. From wearable or man-portable devices to the largest airborne or marine platform, defense electronics are adopting technologies developed in other industries. As defense technology grows more reliant on digital communications, the connectors that link them have become even more essential. A modern platform cannot function without them.

Military Connectors: The Backbone of Modern Defense Electronics

Devices and subcomponents therefore rely on connectors to deliver power, data, and signals. Sensors are linked to processors, power supplies are linked to motors, and displays are linked to networks. Despite this new level of sophistication, the environments in which these systems operate remain some of the harshest encountered in any industry.

High-G maneuvers, shock and vibration, salt-laden atmospheres, electromagnetic interference, and extreme temperatures all act on connectors from the moment a platform is deployed. A connector that suffers even a small loss of integrity can compromise the entire signal chain. For that reason, designers must understand both the challenges involved and the engineering approaches that create long-term reliability.

This article examines five areas where defense-grade connectors must deliver reliability in the face of tough conditions. Each section describes the nature of the threat, from mechanical forces to signal integrity demands. Understanding these challenges allows engineers to select and apply connector technologies that deliver the stability and durability demanded by modern defense platforms.

Challenge 1: Mechanical Shock and Vibration Resistance

These platforms, whether ground-based vehicles, ships at sea, or aircraft, experience significant mechanical stress during their operational lives. The forces vary, from single events that expose components to shock, to less obvious, but just as damaging, long-term vibration.

Typical sources of shock and vibration include:

- Ground vehicles on uneven terrain

- Rotary‑wing aircraft across broad frequency ranges

- Fixed‑wing aircraft during landing or weapons deployment

- Ships exposed to machinery vibration and extreme weather

Each of these environments subjects connectors to persistent mechanical stress, making vibration resistance a critical requirement for long‑term reliability.

Within a connector, even microscopic movement can be dangerous. Fretting corrosion develops when contacts rub against each other in small, repeated motions. This increases electrical resistance, weakens conductivity, and can lead to intermittent or complete failures. A single momentary disruption may be enough to interrupt sensor data, weaken power distribution, or degrade mission-critical communications.

To withstand these loads, connector systems must be mated securely to maintain positive engagement between contacts. They must also prevent shock or vibration from causing connectors to come loose. Connectors with threaded, bayonet, or twist-pin coupling mechanisms are particularly effective in these circumstances, providing enhanced security under dynamic conditions.

Micro-D and Nano-D Connectors for Vibration Resistant Performance

Micro-D and Nano-D systems with machined terminals feature multiple, vibration-resistant points of contact that remain stable even when subjected to irregular vibration patterns. Built to meet the requirements of MIL‑DTL‑83513, these connectors demonstrate compliance with rigorous military standards for durability and reliability. External features including rugged mounting hardware and well-managed cable strain relief prevent forces from being transferred directly to the contact interface.

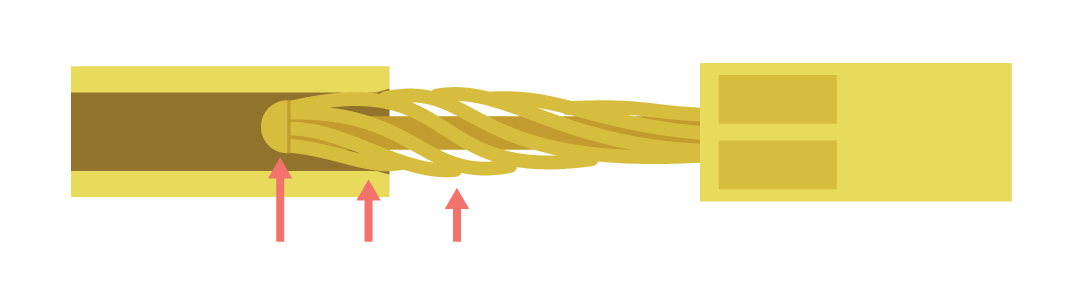

Figure 1: Close-Up of Cinch Twist Pin Contact bulged mating end compresses upon insertion to create uniform radial pressure and multiple micro-contact points.

Before entering service, connectors undergo mechanical qualification testing that mirrors the stresses found in the field. Standards such as MIL-STD-810H and DO-160 require exposure to complex vibration profiles and rapid shock impulses. A connector that passes these tests has demonstrated its ability to maintain electrical performance even during the most intense phases of operation.

Challenge 2: EMI Shielding and Signal Integrity

The modern battlespace has become increasingly crowded from an electromagnetic standpoint. Communications systems, high-power transmitters, active sensors, and countermeasures all operate in close proximity. As a result, defense electronics must contend not only with natural sources of EMI but with interference generated by their own systems.

Connectors play a central role in managing the impact of EMI. A connector that lacks sufficient shielding can radiate unwanted energy or allow external energy to enter the signal path. Mixed-signal assemblies are particularly vulnerable as digital, power, and RF lines often share the same physical routing within a confined space.

Connector Design Solutions for Electromagnetic Compatibility

Designing for electromagnetic compatibility requires the connector to act as part of the system’s protective shielding. Metal housings, conductive gaskets, and fully grounded backshells work together to maintain a continuous shield from end to end. For systems where EMI suppression must be incorporated within the connector itself, filtered circuits can reduce interference before it reaches sensitive circuitry. RF connectors must also maintain precise impedance and low passive intermodulation to preserve the integrity of high-frequency signals.

However, the most effective way to combat EMI is to eliminate it altogether. Optical connectors achieve this by being inherently immune to electromagnetic interference. They do not generate EMI, nor do they allow external EMI noise to affect performance, making them ideal for high-data-rate, mission-critical defense applications.

Compliance with standards such as MIL-STD-461G confirms that a connector can perform reliably within the dense electromagnetic environments typical of military platforms. When paired with careful harness design and proper system-level shielding, these interconnects support stable data flow in even the most complex RF and digital architectures.

Challenge 3: Environmental Sealing and Corrosion Resistance

Defense platforms are deployed in some of the harshest operational conditions. Aircraft traverse rapidly between high humidity and sub-zero temperatures, while naval vessels must withstand the corrosive effects of salt spray and moisture. Armored vehicles encounter dust and grit, as well as fuel and hydraulic fluids. Each of these conditions can compromise unprotected connectors.

Ingress of contaminants is particularly harmful. Moisture or fine particles can increase leakage currents, degrade insulation, or weaken the mechanical connection. Corrosion can alter contact resistance or damage plating layers. Over time, these effects reduce both electrical performance and structural stability.

Effective protection of electrical functions begins with sealing. Many connectors, including those built to MIL-DTL-38999 requirements, are sealed against dust and moisture when mated, and are frequently rated up to IP67 or IP68. Sealed Micro-D and Nano-D configurations extend similar benefits for applications in which space is at a premium and circular connectors are impractical.

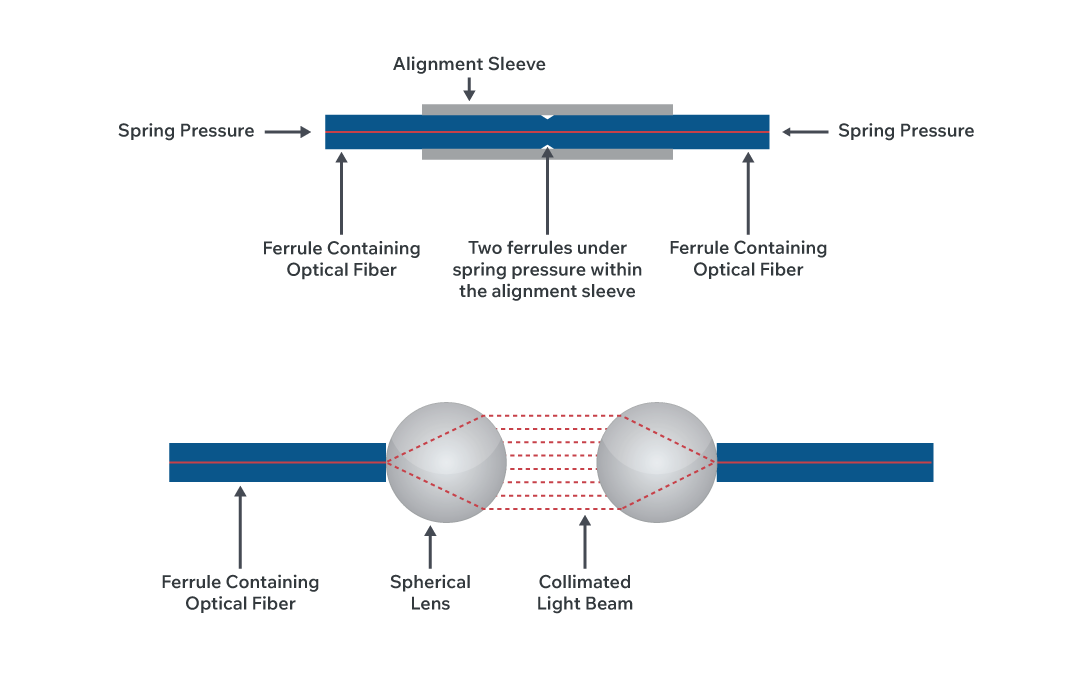

Fiber Optic Connectors: Contamination Risks and Sealed Interface Solutions

Fiber-optic connectors depend on the physical contact of two clean optical surfaces to function correctly and are therefore especially susceptible to contamination. To allow fiber to be used in harsh conditions, sealed termini and elastomeric gaskets prevent foreign matter from degrading the optical interface. In other applications, expanded-beam connectors use a lens-based design to avoid the need for direct physical contact between fiber ends. Unlike physical-contact connectors, an expanded-beam connection can be un-mated, dropped in mud, rinsed off, wiped with a clean rag, and put back into service, whereas a physical-contact connector in the same situation would likely be rendered non-serviceable due to the difficulty of cleaning and re-polishing the fiber ends.

Figure 2. Comparison between physical contact mating (above) and expanded beam components and operation (below).

Material selection also plays a vital role. Aluminum and its alloys are popular construction materials for connectors due to their strength and light weight, but they are particularly vulnerable to salt water. Corrosion-resistant finishes such nickel PTFE, or the use of alternative materials such as stainless steel, provide long-term protection in aggressive atmospheres. Environmental qualification testing to MIL-STD-810H, which includes cycles of humidity, salt fog, and fluid immersion, ensures that each connector retains its protective capabilities during years of service.

Challenge 4: Size Weight Power and Cost (SWaP-C) Constraints

The defense industry shares a particular demand with the wider electronics industry, namely the need to create systems with more capability yet are compact and energy efficient. Size, weight, and power consumption have an impact on every subsystem, particularly those found on the modern battlefield in the form of UAVs and soldier-borne systems. At the same time, cost pressures continue to be a key focus, even in programs that may remain in service for decades.

Connector design plays a major role in meeting these constraints. Smaller connectors with high contact density reduce the space required for cables and harnesses. Micro-Circular, Micro-D, and Nano-D solutions are ideal for compact electronics, while hybrid connectors that combine power, data, and RF within a single housing help to reduce harness size and overall system weight.

Lightweight metals and composite materials further reduce mass without sacrificing durability. Connectors designed with low insertion force reduce wear on mating surfaces, extending operational life and minimizing maintenance requirements. When viewed through the lens of total lifecycle cost, these advantages become especially important. The most effective connector offers predictable performance with minimal upkeep over many years of deployment.

Challenge 5: Ensuring Signal Integrity in Complex Architectures

Data has become the defining force shaping modern defense systems. Integrated into complex networks, the volume of data they handle continues to grow. With the ongoing miniaturization of advanced sensors, even man-portable devices boast high-resolution imaging, radar processing and encrypted communications as standard capabilities. These demands place significant pressure on the connectors that link each subsystem together.

Maintaining signal integrity requires connectors that preserve the electrical or optical characteristics of each signal type. The table below compares RF, fiber‑optic, and high‑speed digital systems with their key connector requirements.

| Signal Type | Connector Design Requirements |

| RF (Radio Frequency) |

Precise impedance control to minimize reflections. Low insertion loss to preserve signal strength. Effective shielding to prevent crosstalk and EMI. |

| Fiber‑optic |

Consistent alignment of fiber termin. Low insertion loss across mechanical shock and temperature cycles. Sealed or expanded‑beam designs to resist contamination. |

| High‑speed Digital |

Controlled differential pair geometry for minimal skew and jitter. Low insertion loss to maintain data integrity. Robust shielding to reduce crosstalk and electromagnetic interference. |

Hybrid or mixed-density connectors provide a practical solution when multiple signal types are required within the same interface. By isolating cavities and shielding sensitive paths, designers can consolidate connections without compromising performance. Verification involves detailed testing of insertion loss, return loss, passive intermodulation, and eye-pattern stability to confirm that the connector can support the requirements of advanced digital and RF systems.

In environments where a single corrupted packet or a minor mismatch can have serious consequences, this level of precision becomes essential. Signal integrity is not simply a performance criterion. It is a prerequisite for mission success.

The Importance of Proven Reliability in Military Grade Connectors

Defense platforms must operate in a world of extremes: mechanical stresses, environmental hazards, and complex electromagnetic conditions. The connectors that serve these systems must maintain their performance throughout every phase of a mission, from pre-flight checks to extended operational deployments. Achieving this level of reliability requires a deep understanding of the challenges involved and the engineering decisions that must be made to address them.

Figure 3. Cinch engineer subjecting component prototype to up close examination and compliance testing.

Cinch engineers apply decades of experience in high-reliability interconnect technology to create connector systems that meet these challenges. Cinch’s portfolio includes expanded beam connectors engineered for extreme environments, Micro D-subminiature connectors with twist pin technology, and Micro-Circular connectors designed for lightweight yet durable interconnect solutions. Cinch also offers a range of RF products that further enhance signal integrity across complex systems. For designers seeking durable, qualified interconnect systems for air, land, maritime platforms, Cinch provides the expertise and technology necessary to ensure dependable performance throughout the full lifecycle of their mission.

Micro-Circular Connectors

Micro-Circular Connectors

Micro-D Connectors

Micro-D Connectors

Expanded Beam Connectors

Expanded Beam Connectors